Non-Viral

Gene Delivery

Lipid Nanoparticles (LNP)

Ionizable Lipids

Shielding Lipids

Sterols

The presence of sterols confers structural integrity to the particle, enhancing its overall stability. Cholesterol is the most frequently used.

Helper Lipids

At Curapath, we excel in optimizing lipid nanoparticle (LNP) formulations to ensure superior performance and efficacy. Our comprehensive services encompass the entire manufacturing process, providing expert guidance from initial design to full-scale production. Utilizing advanced Design of Experiments (DoE) methodologies, we fine-tune the composition and process parameters of LNP formulations for optimal results.

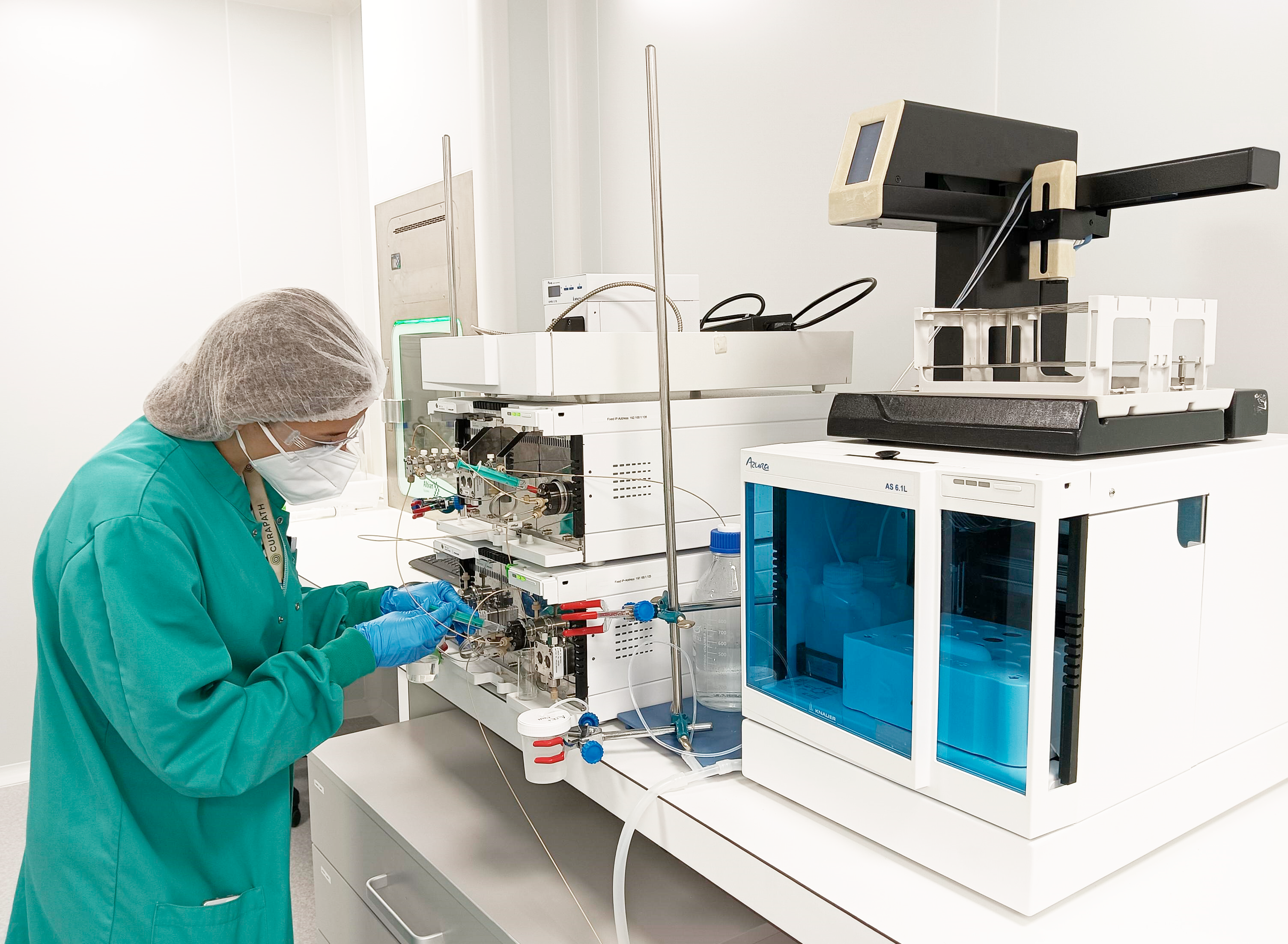

We employ various LNP manufacturing methods, including microfluidics and turbulent mixing (T-Mixing), capable of scaling from milliliters to multi-liter batches of lipid-encapsulated nucleic acids. Our GMP-certified facilities are equipped with the state-of-the-art KNAUER IJM production equipment, enabling the efficient production of large LNP batches to meet clinical and commercial demands. Additionally, we hold vast experience in seamless technology transfer and adaptation of alternative mixing technologies from customers, ensuring smooth transitions and maintaining quality.

Polymer Nanoparticles (PNP)

Polymer nanoparticles (PNPs) are advanced drug delivery vehicles made primarily of polymer functional excipients. They have demonstrated effectiveness in delivering a wide range of therapeutic agents such as hormones, vitamins and larger entities such as oligonucleotides, nucleic acids, and proteins.

PNPs can be precisely engineered for specific size, shape, and stealth properties, enabling them to evade the body’s defense mechanisms and target particular cells and tissues. Their customizable loading capacity, versatility in delivering diverse payloads, and safe toxicity profiles make PNPs highly efficient for delivering various nucleic acids, regardless of their size and chemical nature.

The design of polymer components for non-viral gene delivery depends on the payload, site of action, and route of administration. Key functional excipients include ionizable and shielding polymers, which are essential for optimizing delivery and efficacy.

Ionizable Cationic Polymers

Ionizable and cationic polymers form stable complexes (polyplexes) with nucleic acids through electrostatic interactions, ensuring efficient intracellular delivery. Some examples of efficient complexing polymers are polyethyleneimine (PEI) and polybeta amino esters (PBAEs) among others. Curapath’s also offers proprietary ionizable, and cationic polymers based on polyamino acids which offer unique benefits, including enhanced stability, targeting specificity, and reduced toxicity, significantly improving the therapeutic profile of nucleic acid delivery systems.

Shielding Polymers

LNP/PNP Formulation

The remarkable success of mRNA-based vaccines utilizing lipid nanoparticles (LNPs) has driven pharmaceutical companies to explore LNPs for the therapeutic delivery of nucleic acids.

Producing LNPs is a complex process that demands stability, scalability, and reproducibility. To meet these challenges, we utilize advanced formulation equipment that optimally blends the organic lipid-containing phase with the aqueous nucleic acid-containing phase. Precise control of mixing chamber parameters ensures LNPs with consistent dimensions.

During development, we focus on optimizing LNP/PNP drug formulations by establishing a quality target product profile and a robust process control strategy. Our high-throughput LNP formulation capability exceeds 200 formulations per week, guided by Design of Experiments (DoE) to optimize experimental output. Scaling up the mixing step from benchtop to GMP environments is crucial, alongside a thorough understanding of downstream unit operations such as Tangential Flow Filtration (TFF) and sterile filtration to ensure drug product quality compliance.

Our rigorous approach includes qualifying and validating analytical methods, along with implementing in-process and release controls, to guarantee the highest level of product quality. This comprehensive methodology ensures that your LNP formulations are safe, efficient, and ready for clinical use.

In 2021, Curapath established a collaborative agreement with KNAUER to install multiple Impingement Jet Mixing (IJM) instruments for producing robust LNP formulations. The effectiveness of KNAUER’s IJM technology has been proven in the large-scale production of recent FDA approved LNP-based vaccines. Along this process, Curapath has augmented its technical proficiency in the development, optimization and in-house formulation of LNPs. We are capable to produce from one milliliter to multi liters of LNP formulations with reproducible characteristics and performance. We cover any LNP related need from R&D to GMP commercial scale.

At Curapath, we excel in replicating virtually any LNP formulation by adjusting key operational parameters such as flow rate, mixing geometry, and component ratios.

We maintain flexibility in our LNP manufacturing methods, having successfully completed numerous projects involving technology transfer of various LNP mixing technologies from our customers. We are committed to using your preferred instruments and formulation protocols to ensure your complete satisfaction.

To facilitate seamless technology transfer, if needed, we deploy a team of visiting scientists to your facilities to thoroughly understand your processes, analytical methods, and qualification criteria. Additionally, we can host your formulation experts at our facilities and eventually acquire your preferred equipment. This knowledge is then implemented in-house, ensuring the production of LNP drug products that meet your exact specifications.